Its been about 10 months since the worlds. A pretty good amount of time to rest, digest new information, work on other things etc etc. But, the itch to go sailing is back and I now have a Doink-built Alpha shell (thanks mate!) sitting in the garage waiting to get turned into a new boat.

So, the plan was to start with the most outrageous contraption possible, and gradually change it into something that sort of worked. I'm not sure about that plan anymore, due to day to day time constraints and the pressures of modern life and whatever else. So, I've decided to go with something more conventional. Evolutionary rather than revolutionary, and maybe then try and put a wing on it.

But, it seems like a waste to just chuck ideas away, so I decided to post some things I've been thinking about on here, maybe generate a bit of discussion and possibly inspire someone else to take it a step or two further. They might trickle in, but here's the first one.

The canting foil.

After an initial thought experiment and then some basic 2d cad "calculations," I decided that this would probably be worth a try. But a discussing it with Nick and Markla, we came to the conclusion that it was going to be a lot of work and structural compromise for no a huge gain. Markla did a few proper numbers to illustrate this point. Anyway, I'm still not completely discouraged and it will just go on the back burner I think!

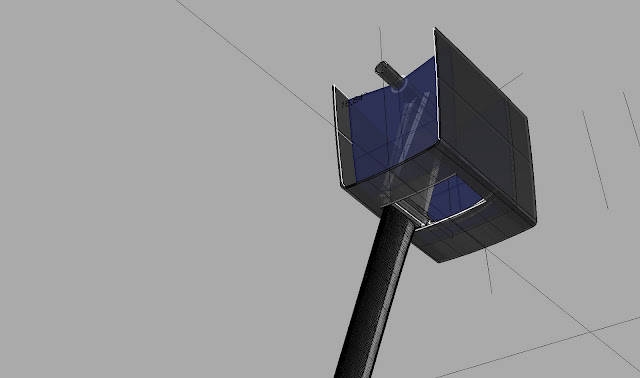

The system I arrived at to make this work is as follows: The foil cants side to side about a bearing mounted at deck level. Very important to have the bearing on the deck, as you seem to get absolutely no advantage over a fixed foil with it at the keel. The bearing needs to be pretty snug, so there are replaceable nylon inserts inside the carbon tube. The centreboard case is supported from the top, but a sliding 'car' that runs along a bit of aluminium bike rim acts as a third point in case you hit a sand bank. I was initially thinking of using a stainless lead screw to control the cant, but decided there was too much machining involved, so I went for an 8:1 purchase system running through laminated-in thimbles. The purchase would need a serious amount of pre-tension in the form of a big bungee to compensate for the changes in line length between 'centred' and 'canted'. Even so, you would never achieve the stiffness from the foil that you get from a fixed centreboard case. That's probably the biggest trade-off. Another issue is that you're left with a large hole in the bottom of the boat, which is among other things a structural problem. This is overcome by some longditudinal bulkheads that tie the fore and aft bearings into the chines and act as beams to stop the hull from snapping. A laterally sliding carbon plate, flexible in one direction only, sits around the base of the foil and fits into a specially moulded carbon groove at the front and back of the hole (not modeled, quite difficult to draw actually) and a small fixed venturi drains it.

In the end, the foil can cant through about 15 degrees comfortably, which is all you would need. From a sailing point of view, i envisaged that the controls would be quite lightly loaded and accurately adjustable. You would probably just centre it in the tacks and when sailing downwind. its an upwind device really.

So, the plan was to start with the most outrageous contraption possible, and gradually change it into something that sort of worked. I'm not sure about that plan anymore, due to day to day time constraints and the pressures of modern life and whatever else. So, I've decided to go with something more conventional. Evolutionary rather than revolutionary, and maybe then try and put a wing on it.

But, it seems like a waste to just chuck ideas away, so I decided to post some things I've been thinking about on here, maybe generate a bit of discussion and possibly inspire someone else to take it a step or two further. They might trickle in, but here's the first one.

The canting foil.

After an initial thought experiment and then some basic 2d cad "calculations," I decided that this would probably be worth a try. But a discussing it with Nick and Markla, we came to the conclusion that it was going to be a lot of work and structural compromise for no a huge gain. Markla did a few proper numbers to illustrate this point. Anyway, I'm still not completely discouraged and it will just go on the back burner I think!

The system I arrived at to make this work is as follows: The foil cants side to side about a bearing mounted at deck level. Very important to have the bearing on the deck, as you seem to get absolutely no advantage over a fixed foil with it at the keel. The bearing needs to be pretty snug, so there are replaceable nylon inserts inside the carbon tube. The centreboard case is supported from the top, but a sliding 'car' that runs along a bit of aluminium bike rim acts as a third point in case you hit a sand bank. I was initially thinking of using a stainless lead screw to control the cant, but decided there was too much machining involved, so I went for an 8:1 purchase system running through laminated-in thimbles. The purchase would need a serious amount of pre-tension in the form of a big bungee to compensate for the changes in line length between 'centred' and 'canted'. Even so, you would never achieve the stiffness from the foil that you get from a fixed centreboard case. That's probably the biggest trade-off. Another issue is that you're left with a large hole in the bottom of the boat, which is among other things a structural problem. This is overcome by some longditudinal bulkheads that tie the fore and aft bearings into the chines and act as beams to stop the hull from snapping. A laterally sliding carbon plate, flexible in one direction only, sits around the base of the foil and fits into a specially moulded carbon groove at the front and back of the hole (not modeled, quite difficult to draw actually) and a small fixed venturi drains it.

In the end, the foil can cant through about 15 degrees comfortably, which is all you would need. From a sailing point of view, i envisaged that the controls would be quite lightly loaded and accurately adjustable. You would probably just centre it in the tacks and when sailing downwind. its an upwind device really.